Introduction

Unplanned equipment failures are one of the largest hidden costs in manufacturing; some industry analyses estimate that unexpected breakdowns can cost factories billions annually. AI-driven predictive maintenance and automated inspection let manufacturers detect anomalies early, schedule repairs proactively, and avoid costly stoppages.

Main questions

- What is AI in manufacturing and how does it work?

- What data and infrastructure are required?

- Which problems does AI solve first on the factory floor?

- How much downtime reduction can companies expect?

- What are the main risks and how can they be mitigated?

How AI reduces downtime

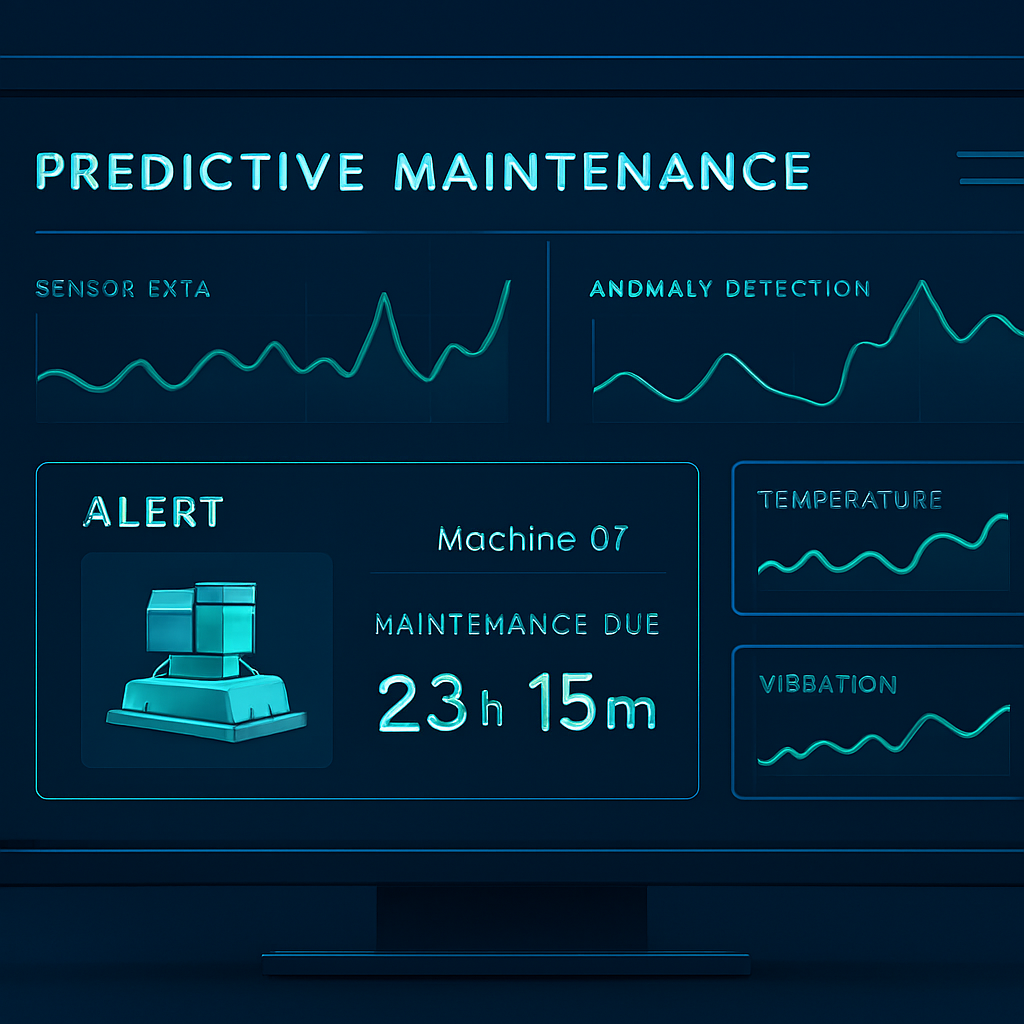

Predictive maintenance

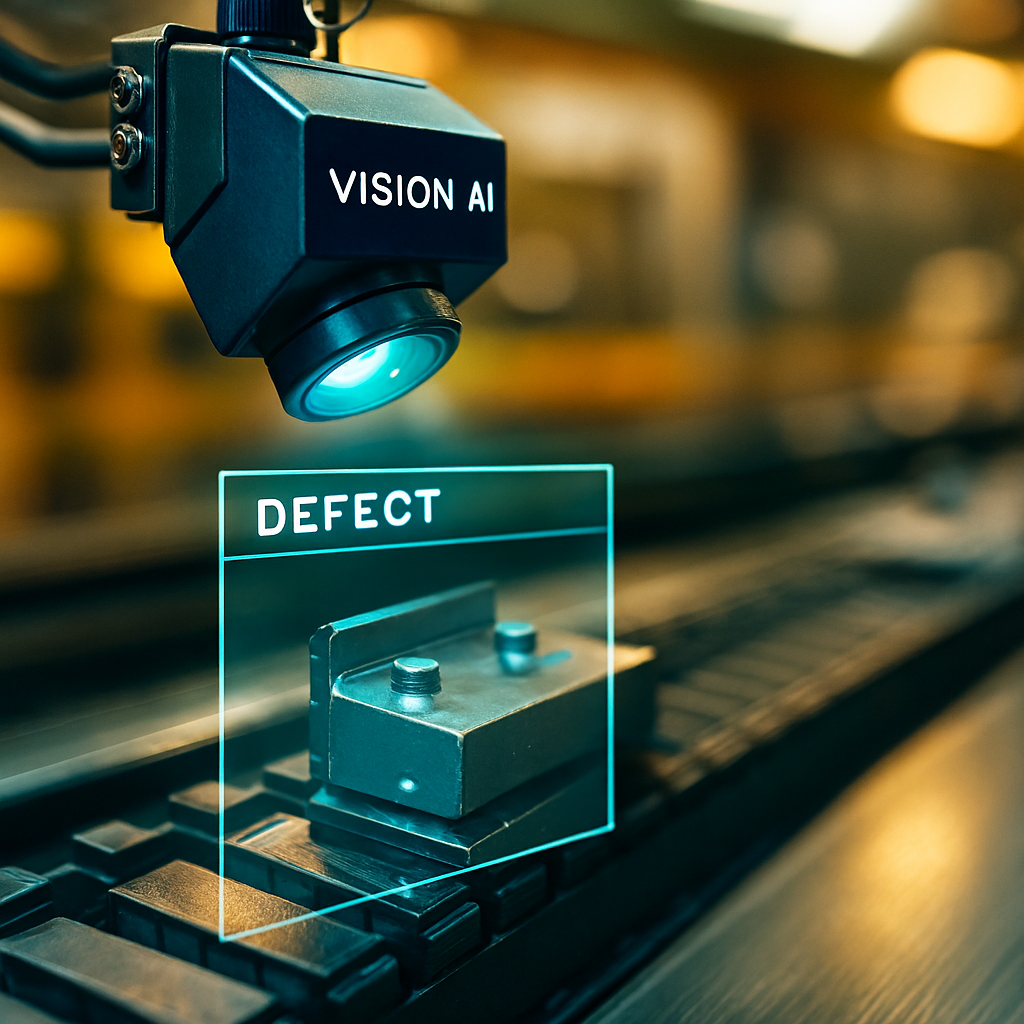

uses IoT sensors and machine‑learning models to spot patterns that precede failures, replacing purely reactive or calendar‑based servicing with data‑driven forecasts. Process automation and computer vision inspect parts at line speed, catching defects before they propagate downstream. Together these systems shift maintenance from emergency fixes to planned interventions, improving uptime and safety.

Predictive Maintenance

Vision at Speed

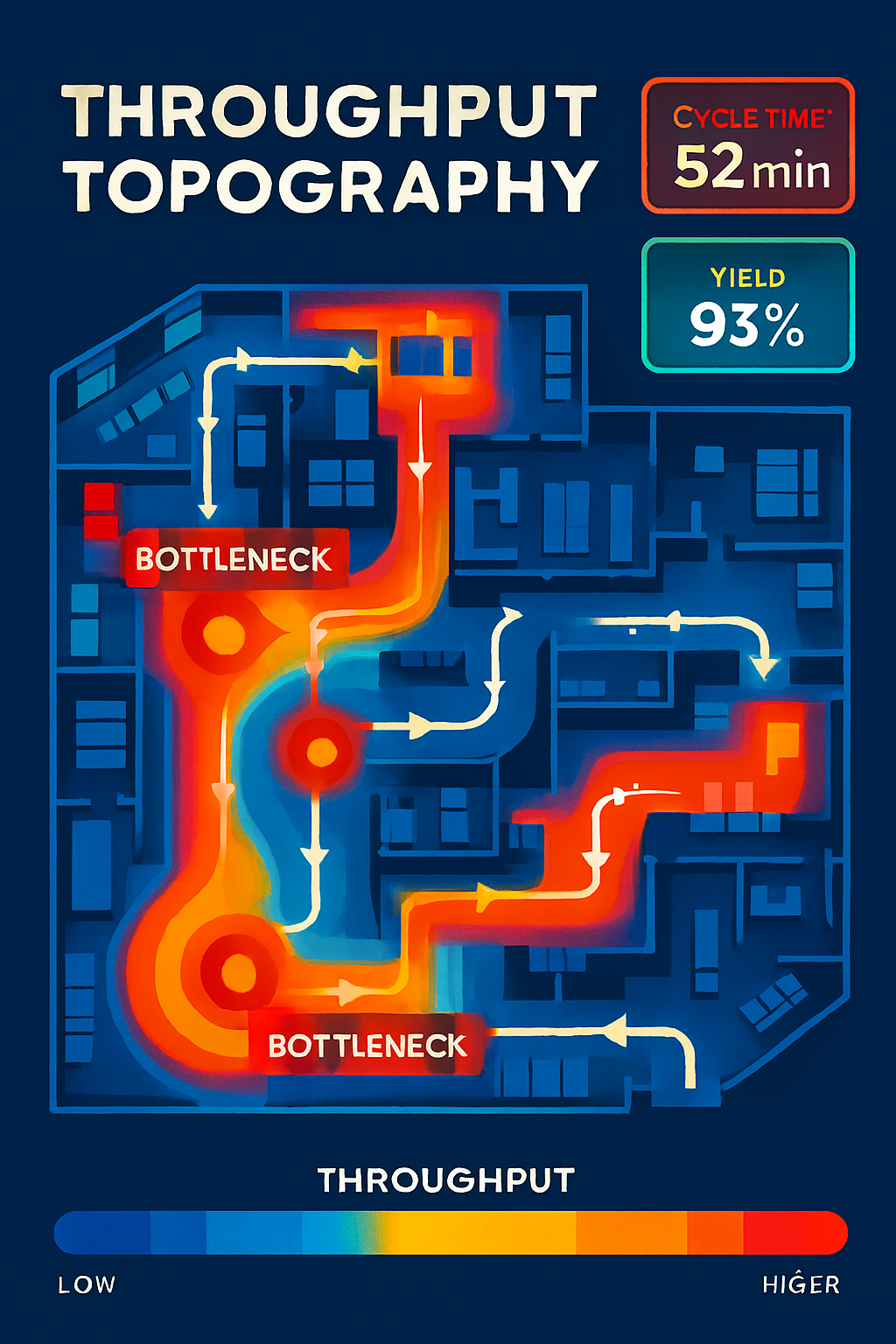

Throughput Topography

Measurable impacts

Field reports and vendor analyses show substantial reductions in downtime and maintenance costs when predictive systems are implemented: typical benefits include lower unplanned downtime, extended asset life, and optimized spare‑parts inventories. Organizations often report double‑digit percentage improvements in availability and meaningful cost savings within months of a successful pilot.

Conclusion

AI in manufacturing delivers real, measurable value when applied to well‑scoped problems

such as predictive maintenance and automated inspection. Start with a focused pilot, measure outcomes against clear KPIs, and prioritize data quality and human oversight to turn early wins into sustained productivity gains.